Customization and processing

customization process

preliminary negotiation

Communicate your specific application scenarios, performance requirements and space constraints. Our technical team will confirm the product model, specifications and customisation requirements accordingly to ensure that the solution is accurately matched.

Programming and quotations

Based on technical confirmation, we provide a detailed proposal with product specifications, price, delivery time and terms of service to ensure transparency and provide a clear basis for your decision.

Sample testing and validation

We prioritise the sending of samples for you to carry out comprehensive performance and compatibility testing. This phase is designed to ensure that the product fully meets your design requirements through practical verification.

Contract signing and first order placement

After sample confirmation, both parties formally sign the supply contract and quality agreement. Upon receipt of your first formal order, we will start the production scheduling process to ensure on-time delivery.

Volume Delivery and Continuous Service

Entering the stage of stable cooperation, we guarantee the reliable supply and consistency of bulk products. At the same time, account managers provide exclusive services and make regular return visits to ensure smooth and worry-free long-term co-operation.

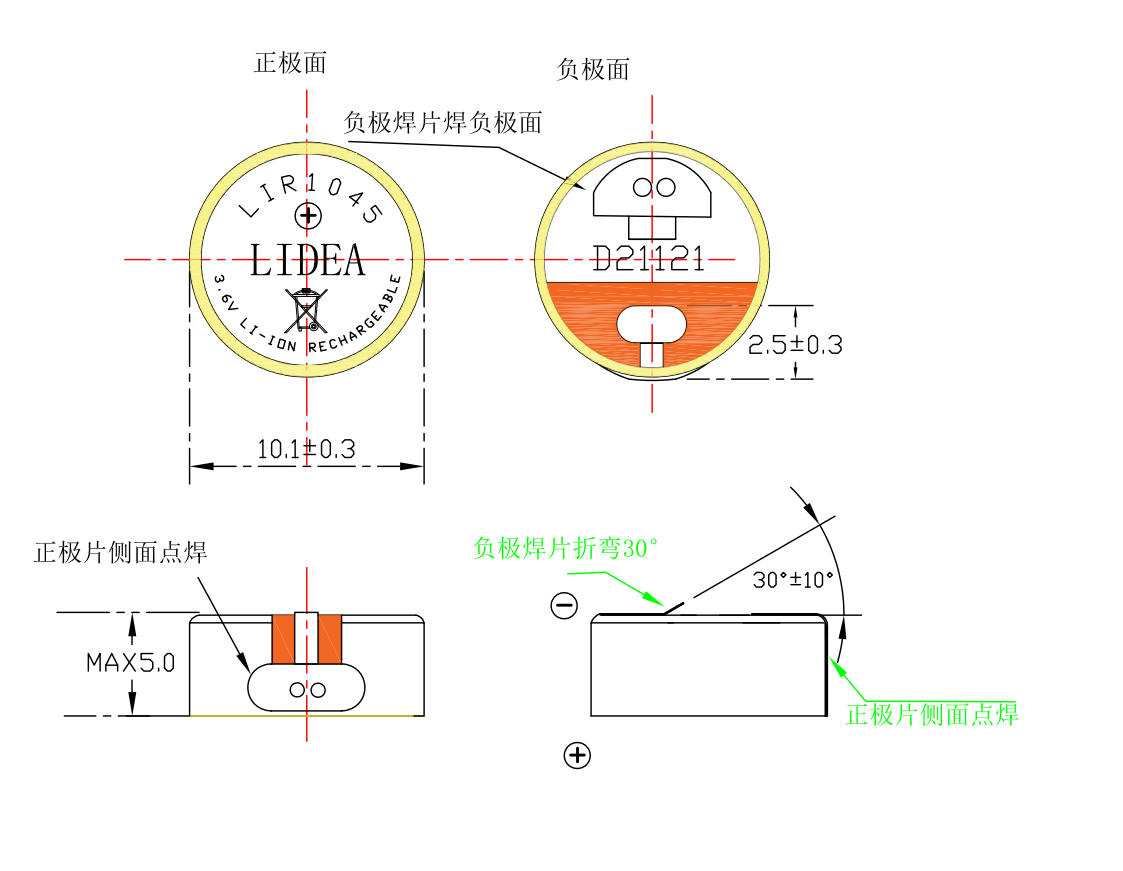

solder sheet

Through resistance welding or ultrasonic welding, metal connectors such as nickel sheets are fixed between the electrode and the shell inside the battery to form a rigid support structure. This method can effectively resist the impact of external forces such as vibration and drop, and avoid the problem of power failure caused by poor electrode contact. It is common in complex scenarios such as vehicle equipment and industrial sensors. After welding, a tensile test is required to ensure that the mechanical strength meets the standard.

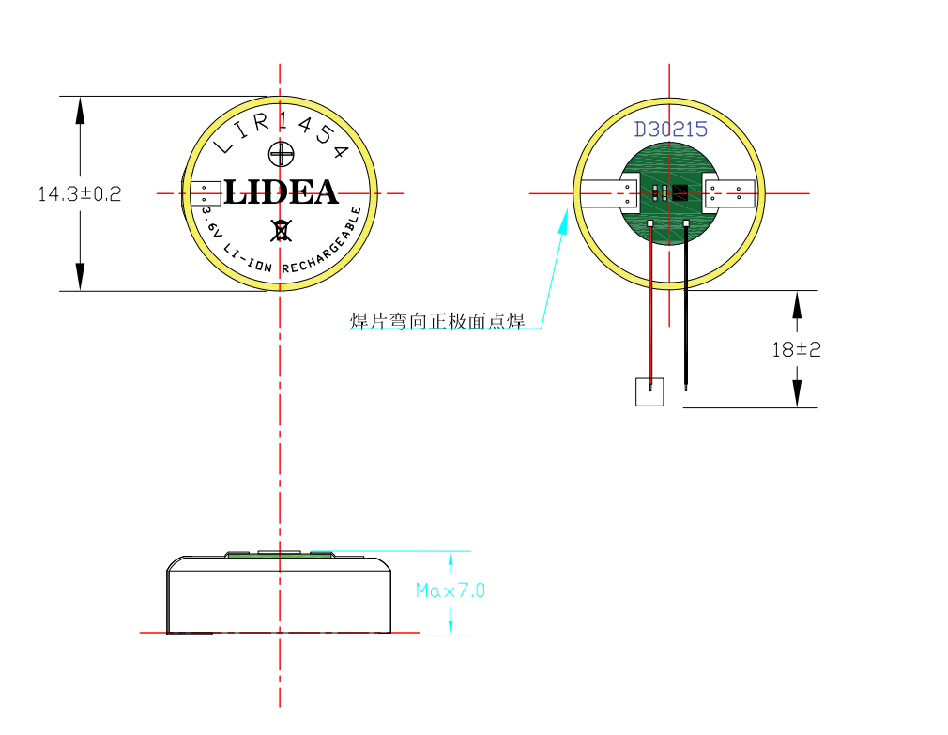

Protection circuit

The miniature PCB protection board is welded in series on the negative electrode of the battery, and the overcharge, over discharge and short circuit protection circuits are integrated. The current state is monitored in real time by temperature sensor and MOS tube. The circuit is automatically cut off when abnormal, and the fault response time is less than 50 ms. It is mostly used in Bluetooth headphones, medical equipment and other fields with high safety requirements.

Welding wire processing

Using high-precision spot welding or laser welding technology, conductive materials such as nickel-plated steel strips are firmly connected to the positive and negative poles of the battery and extended to the external wire interface. This method can ensure the stable transmission of micro-current, and is suitable for micro-devices ( such as hearing aids, smart watches ) that are sensitive to voltage fluctuations. During the welding process, the temperature and pressure should be accurately controlled to avoid damage to the internal structure of the cell, and the oxidation resistance treatment should be used to improve the durability of the interface.